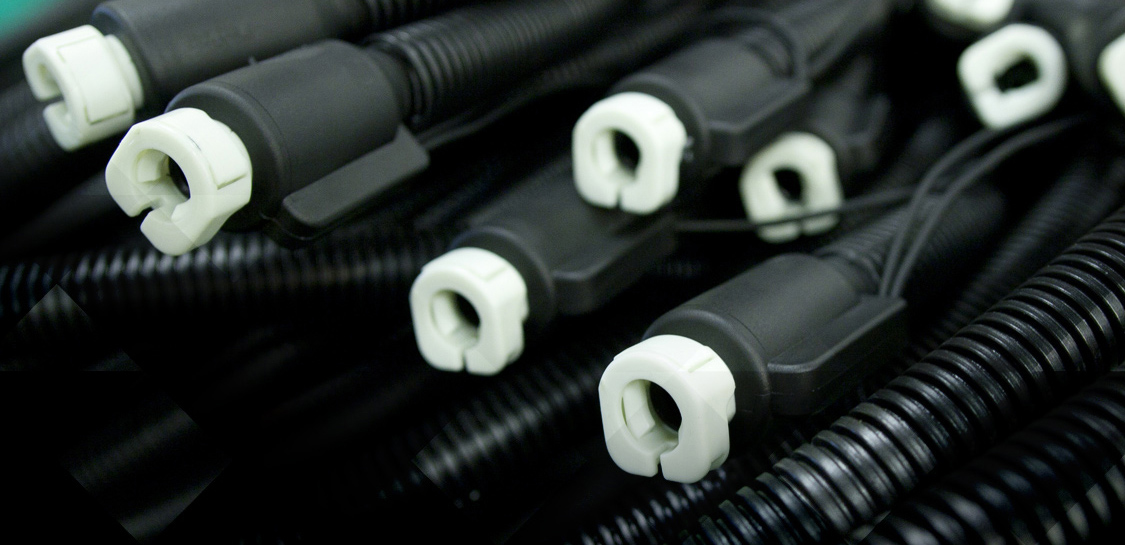

From concept to finished product, MJM Industries can produce overmolded cable assemblies that ensure your parts are manufactured to demanding standards. Custom tooling and fixture design is offered through our molds, assembly fixtures- lean/ergonomic, custom gauges and measurement equipment, and manufacturing process support. MJM Industries has the capabilities to produce overmolded cable assemblies that offer vertical inject and vertical platens with clamping ranges from 5 to 33 tons and auxiliary core pull capabilities.

Tooling charges can be excluded from your order when we are able to utilize molds from prior orders. With over 30 years of combined experience in the design and development of distinct molded, over molded and insert molded products. This makes MJM Industries a global leader in the design and manufacturing of custom over molded cable assemblies, over molded parts and potted components for all markets.

MJM Industries has the capabilities to satisfy all customer needs with our variety of manufacturing services. Our services include over molding, injection molding, insert molding, tool design, molding presses range from 5 through 33 ton, chilling and heating of molds, material drying, material mixing, re-grind and re-processing.

Our product design is performed several different ways, depending on the product, to ensure the best finished product possible. Our product design includes Solid Works 3D, Auto Cad 2D, reverse engineering, prototyping, product and process development, and 3D printing

Our tool room is fully equipped, giving us the abilities for prototyping, on-site mold fabrication, fixture and tool building, and preventative maintenance.

Because of our latest technology and processes MJM Industries has the ability to create low to high volumes with many overmolding machines on site. Our custom design services offer customers with the exact products they need, let our high quality products assist you in making your product with the best possible performance. Our complete program of over molding and potting will exceed all of your product needs. We offer a wide variety of encapsulating materials and connectors which will accommodate all your requirements.

Molding Materials:

- PVC – Polyvinyl Chloride

- TPV – Thermoplastic Vulcanizate

- TPR – Thermoplastic Rubber

- TPE – Thermoplastic Elastomer

- LPC – Liquid crystal Polymer

- Other materials are available upon request

Molded Connector Options:

- D-Subs

- Circular Connectors Metal/Plastic

- Mini Dins

- Ferrites

- Strain Reliefs

Potting:

- Circuit Boards

- Connectors

- Switches

- Box Enclosures

- Semi- automatic mixing/dispensing equipment

- Custom Molds

- UL94V-O rated compounds

Optional Features:

- Mil Spec

- Logos

- Custom Color – Pantone Color Chart

- Ingress Protection

- UL Registered Components

- Special packaging

- Inventory program

We have worked alongside automotive, off-road vehicle, aerospace, military and defense, medical,

industrial automation and consumer products. MJM Industries has developed solutions for some of the

most difficult problems in a variation of areas. Our team is fully equipped to assist your team with any

project from small to large volumes.