What is ingress protection, why is it important and where is it used? Ingress protection provides

wire harnesses and cable assemblies with long-standing quality, which is crucial when placed within dusty or

damp environments. The IP rating of a product sometimes known as Ingress Protection or International

Protection Rating classifies and rates the degree of protection provided against intrusion, dust,

accidental contact and water. Contaminants can enter electronics by infiltrating enclosures, casings,

splices and connectors which can damage the electronic permanently. To prevent such damage, a

barrier is installed between the product and the environment to protect the wiring and cables,

increasing the life expectancy of your product.

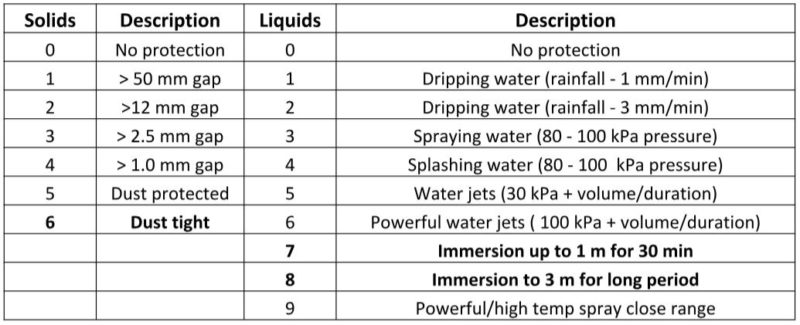

The industry standard for a products ability to resist dust and moisture is identified by a series of letters

and numbers, the first being IP for ingress protection and the second two, for purposes of this article, as

XY. For a product with a rating of IP68, the first number (X), or 6 in this example, stands for the level of

solids (dust, dirt, etc.) which the assembly is protected against and the second number (Y), or 8 in this

example, stands for the level of liquids which the assembly is protected against.

The level of protection increases when the number for X and Y also increase. XY have ratings for dust

and dirt from 0 to 6 and for liquids 0 to 9, respectively. On Table 1, a list of rating values and

descriptions of the corresponding level of protection is provided. It is important to test and rate

products since dust and water are capable of accumulating inside of ports, sockets, and other openings

of electronics, causing failure. If occurrences of undesired materials occur, the electronic device may

experience poor electrical conductance or short, causing damage to the device or product in which it is

attached. Instances where IP ratings are needed include sealed products in hazardous locations,

outdoor products such as lighting, pumps or communication devices, products susceptible to dust,

products in damp locations, electrical enclosures, hand held controls and electrical medical equipment.

Since wire harnesses and cable connections must be able to withstand dirt and moisture in order to

perform properly, MJM Industries offers the ability to add ingress protection. By working with

customers to choose the correct types of connections and develop molded solutions, MJM Industries

can design a molded solution with ratings for solids in the range of 0 to 6 and moisture from 0 to 8.

Utilizing an over-mold can not only provide ingress protection, but a mechanical strain relief, additional

protection for rough environments and ability to design in features for attachment, caps and logos. Our

molded solutions have the ability to allow your product to maintain durability throughout its lifespan,

even in abrasive and vibration related conditions (additional testing may apply). Our team is available to

provide you suggestions to meet your IP needs. All testing or certification requirements are conducted

by a third party group at your request.

The table displayed exhibits the Ingress Protection levels rated according to IEC standard 60529.