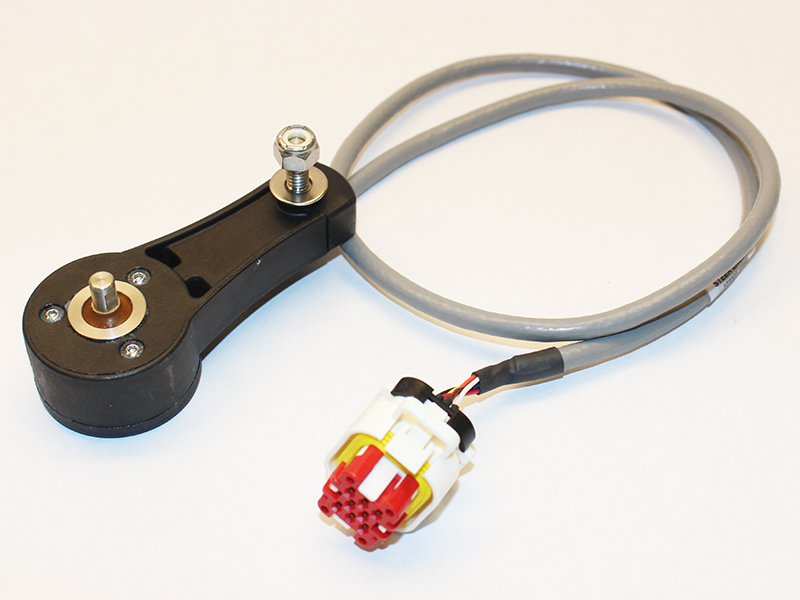

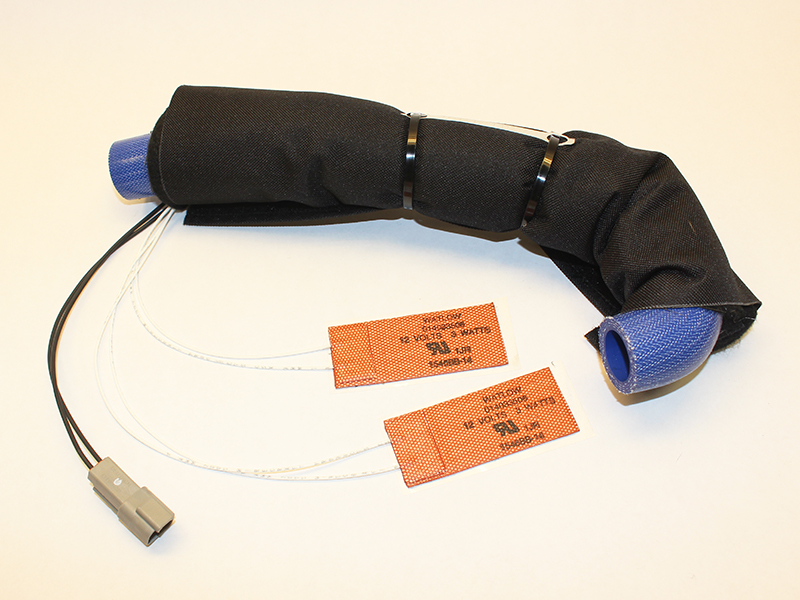

Cable Assemblies and Wire Harnesses

From high to low volume, MJM Industries has the knowhow, equipment and personnel to provide the best wire harnesses and custom cable assemblies for your products.

At MJM Industries, we can help design and manufacture assemblies with cable or wire harnesses for any application that demands reliable, high-quality products. Our design and manufacturing equipment capabilities allow us to process most types of wire and cable with a large variety of terminations and connectors and just about any length.

Although both products can provide a similar solution, differences exist between wire harnesses and cable assemblies.

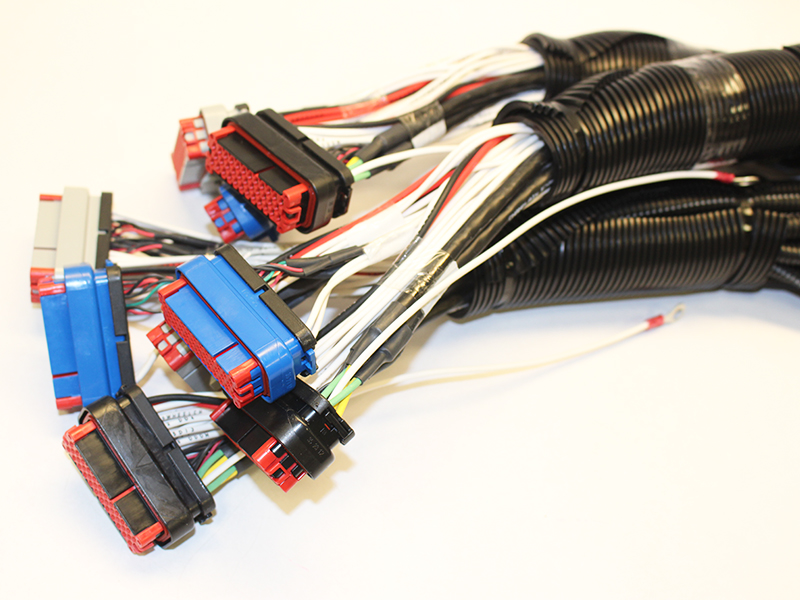

Wire harnesses are typically made up of discrete wires and terminated with a combination of terminals (rings, forks, sockets, and pins) or simple connectors that are crimped onto the individual wires. Harnesses allow for branching off to multiple connection points and permit the inclusion of secondary jackets such as loom or spiral wrap. Harnesses may also include labels attached to each conductor and ty-wraps to designate bend locations.

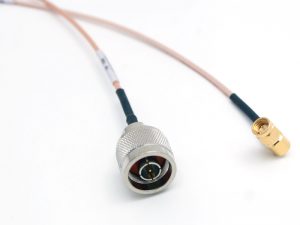

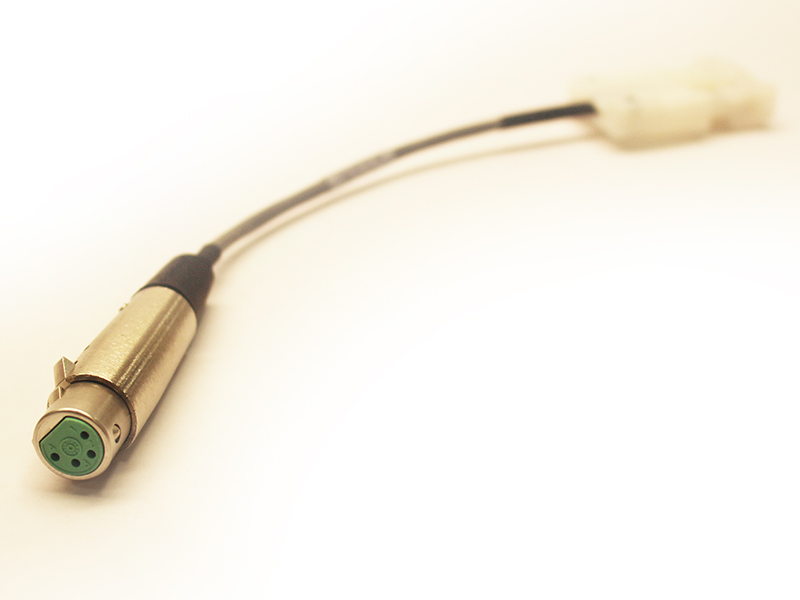

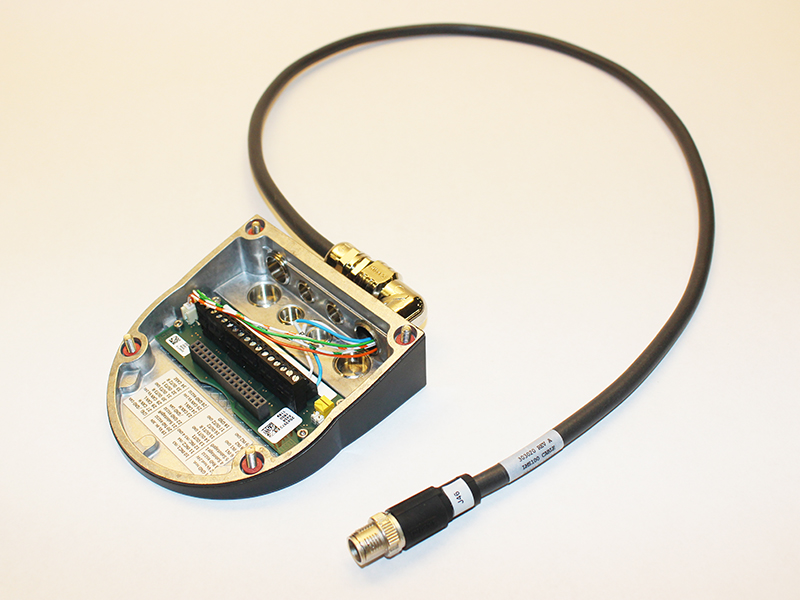

Cable assemblies are designed around a specific cable(s) that include several conductors within an outer jacket. They can be easier to route around obstacles and generally have two connection points, although branching can be done if required.

It is not unusual to include processes such as soldering and crimping as a method of connector attachment and it is not uncommon to request overmolding connectors in order to provide some level of ingress protection between cable and connector.

Some of the materials used on the assemblies we have produced include:

- Multi-conductor cable

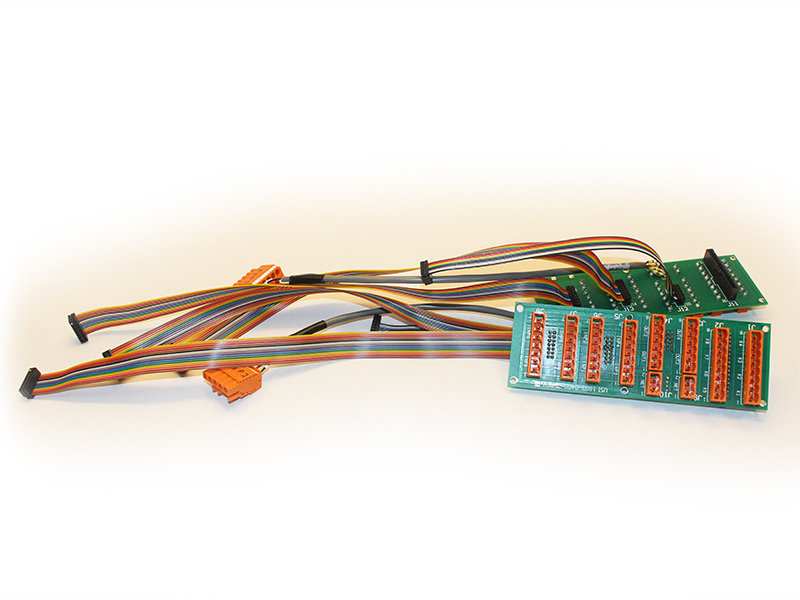

- Flat ribbon cable

- Round-flat ribbon cable

- Discrete wire

- Co-axial RF cable

- Large gauge Power cable

- Ethernet Cable – Cat 5

- Composite cable

A Leading Manufacturer of Custom Cable Assemblies and More

In addition to wire harnesses and cable assemblies, we provide a full range of services to complement contract manufacturing. Our services include:

- Product design and process development

- Tooling and fixture design

- Mold design and build

- Custom testing

- Box build and product integration

- Product identification and labeling services

- Logistical services

- Packaging

- And a variety of other value-added services!

Our Wire Harness Manufacturing Process

Located in northeast Ohio, our state-of-the-art facility is fully equipped to handle high and low volume orders of custom cable and harness assemblies of any size. Our automated and semi-automated equipment allows us to process UL and non-UL types of wire with various insulations and cable from 4/0 to 32 gauge.

Cutting

Depending on the wire or cable being processed, there are several options for cut and strip machines, de-reeling stations, and coiling systems to be employed. Cutting and stripping can be completed with either “V” style, die blades, or rotary cutters to ensure the best possible strip.

Dereeling systems allow for 10″ reels at 2 pounds all the way up to four-foot reels weighing in at several hundred pounds. An attachment to each of our wire processing machines, automated coiling systems provide options when running lengths longer than four to five feet. For short runs of very large gauge cable 2AWG – 4/0 and heavy reels, MJM has a custom-built system to measure and payoff long lengths of cable into individual coils.

Stripping

Removing insulation from conductors may sound simple, however, there exists a science around proper methods. At MJM Industries, we utilize mechanical “V” blades, custom die blades, thermal and chemical processes, as well as dual-axis laser systems.

Each method is determined by volume, speed, wire size, jacket material, end product application, and total cost.

Typically, a mechanical means of wire stripping is most cost-effective and is used in high-volume applications. With the correct blades, both the strip quality and output can be effectively maintained well within the requirements laid out in the IPC-620 workmanship standard.

For those requiring Class III workmanship, our laser wire stripping machine offers a practical solution for accurately stripping small diameter wires and unsymmetrical shielded cables. This highly precise process eliminates the risk of mechanical damage to internal insulation materials and the conductor while stripping ends, along with performing cross cuts, windows, and patterns, depending on your requirements.

Our laser wire stripper is a computer-controlled machine that uses a laser to burn off the insulation of the wire. Although it takes more time to process, resulting in a slightly higher cost, this precise wire harness manufacturing process allows us to offer repeatable results when processing multiple wires and cables simultaneously.

Terminations

The attachment of terminals and connectors can be done with several methods. At MJM Industries, these methods include crimping, traditional soldering, reflow solder technology, and ultrasonic welding. While crimping is used in 80% of all applications, soldering can provide a permanent connection that acts like a “glue” that holds electrical parts together.

A final method is ultrasonic welding for the splicing of wires and/or cable assemblies. This method uses high-frequency vibrations, removing the need for mechanical crimp connections, and offers very fast and efficient results with repeatable welds. The welds are also more durable (rugged) than other traditional methods of joining which improve product reliability.

Looking for a Dependable Custom Wire Harness Manufacturer? Choose MJM Industries

Searching for a reliable and experienced custom wire harness manufacturer? MJM Industries is fully committed to quality assurance and providing our customers with high-quality cable assemblies. We are compliant with a variety of U.S. and international standards including:

- ISO 9001:2015 certified

- Underwriters Laboratories

- IPC/WHMA-A-620 and IPC-A-610 manufacturing workmanship standards

- ITAR compliant and Registered with the State Department

- Compliant with the Securities Exchange Commission’s Conflict Minerals Rule

- RoHS and WEEE Compliant

Our Experience

No task or request is beyond what we’ve probably already experienced.Our Experience

MJM Industries has produced millions of wire harnesses and cable assemblies that have made their way into thousands of products around the world.

Our Quality

We stand behind every assembly that leaves our facility.Our Quality

You can rest assured that your project is exactly what you expect. We don’t just spot check our work, but each assembly is inspected and tested for accuracy and quality.

Our Team

We've assembled a team of experts that specialize in assembly.Our Team

From engineers, to project managers, to plant managers, our team of experts come together to provide exactly the products you’re counting on.

Our Commitment

To provide our customers solutions that exceed expectations.Our Commitment

Our daily mission is to provide our customers engineering and manufacturing solutions resulting in products and services that exceed their expectations.

Cable Assemblies for Any Industry

As a leading contract manufacturer, we strive to deliver reliable products backed by exceptional customer service to clients in any industry. Some of the industries we work with include:

- Defense and military

- Consumer products

- Industrial automation

- Communication

- Medical equipment

- Mass transit

- Water equipment

- Commercial off-road

- Utilities

- Heavy equipment

- Appliance

- Test and measurement

- Transportation

- Aerospace

As a contract manufacturer, MJM Industries offers a variety of manufacturing processes and other value added services that allow our customers to realize greater productivity and profitability. From design services to custom overmolding, cable assembly, packaging, and testing, we strive to provide a complete contract manufacturing program for customers that demand reliable assemblies with on-time delivery.

Contact us for cable assemblies and wire harnesses.

Call us. Email us. Or use the form below.

Either way, we’re ready to help make your job easier!