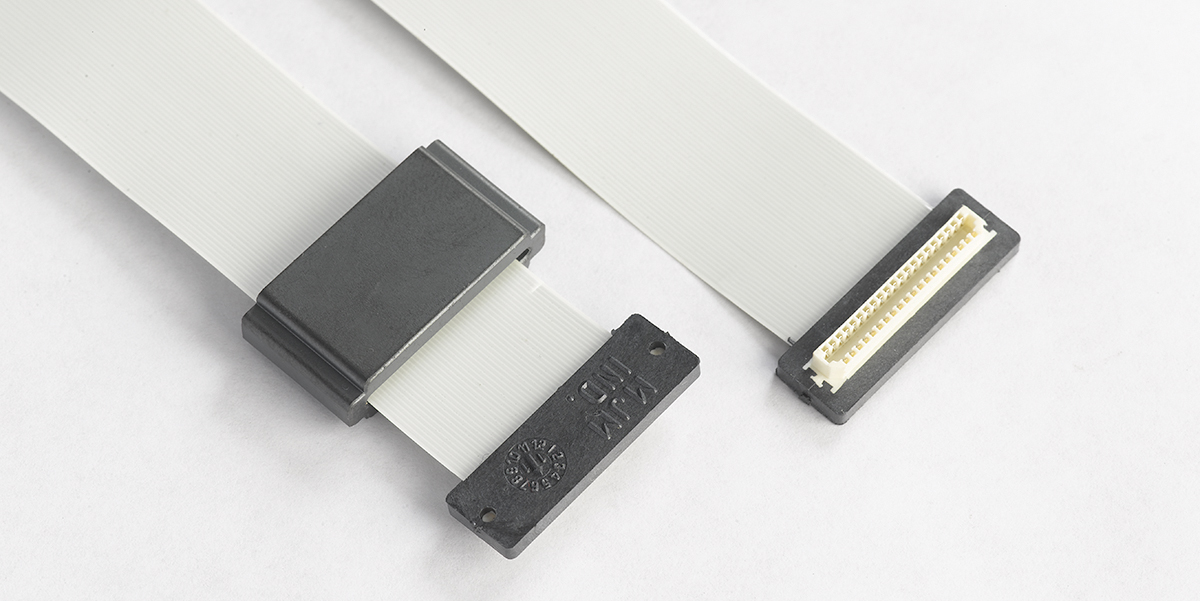

Not every project can rely on an off-the-shelf flat flex cable. When unique designs, specialized terminations or ruggedization are required, custom flat flex cable assemblies provide the flexibility and reliability to get the job done.

At MJM Industries, we engineer and manufacture custom flat flex cable assemblies in the U.S. to meet exact performance, space and durability requirements across industries from medical devices and avionics to industrial automation and display technology.

Why Choose Custom Flat Flex Cable Assemblies?

Standard flat flex cables work well in many consumer and commercial products, but specialized applications often demand more. Choosing custom flat flex cable assemblies ensures:

- Tailored fit and function: Exact lengths, pitches and connector types to integrate seamlessly with your system

- Enhanced durability: Options for overmolding, shielding or reinforcement to withstand flexing, vibration or harsh environments

- Improved performance: Optimized for signal integrity, EMI protection or space-saving routing

- Application-specific compliance: Built to meet industry requirements for medical, aerospace, industrial and automotive applications

Custom solutions help you avoid the compromises of off-the-shelf parts, giving you a reliable interconnect built for your unique needs.

Custom FFC Design Flexibility for Complex Applications

Our custom flat flex cable assemblies can be engineered to suit both simple and complex projects. MJM Industries offers a broad range of options, including:

- Foil shields

- Separated lead ends

- Selective grounding

- Ferrites

- Specialty pin-outs

- Custom cable lengths

- Transition boards

We maintain a fully equipped machine shop for custom tooling and fixtures and support new product development with prototyping and 3D printing capabilities. For branding needs, your logo can even be added to the finished cable.

Custom Overmolding and Shielding Options

Flat flex cables are often exposed to stress, vibration and interference that standard assemblies can’t handle. Our custom capabilities extend protection and reliability with:

- Overmolded strain reliefs to reduce flexing and extend cable life

- Sealed overmolds for resistance to moisture, dust and contaminants

- EMI/RFI shielding for reliable performance in noisy environments

- Reinforced terminations for high-flex or high-cycle applications

MJM also uses a proprietary liquid crystal polymer (LCP) overmolding process that provides strength and environmental protection without sacrificing flexibility.

Precision Engineering for Reliable Performance

Custom flat flex assemblies are only as strong as the processes behind them. At MJM Industries, we apply in-house engineering and strict quality systems to every build.

- Manufactured to IPC/WHMA-A-620 standards

- Testing ensures both electrical and mechanical integrity

- Expertise in fine-pitch conductors and complex terminations

- Multiple joining processes, including hot bar bonding, soldering, and welding

The result: repeatable assemblies that stand up to the most demanding environments.

Compliance and Material Options

Our custom flat flex cable assemblies are engineered for compliance with RoHS, REACH, and WEEE directives. Standard materials include:

- Copper alloy or tinned copper conductors

- Gold or tin plating for connectors

- UL-approved insulation materials

- Tolerances designed to ensure precision in high-density applications

U.S.-Made Custom Cable Solutions

As a U.S. manufacturer, MJM Industries provides responsive engineering support, shorter lead times and supply chain security. Our family-owned operation combines decades of experience with a full range of tooling, molding and machining capabilities to produce assemblies built to your exact specifications. Whether you need prototypes or full production runs, we deliver custom flat flex cable assemblies that connect what matters most.

Build Your Custom Flat Flex Cable Assembly with MJM

When standard cables won’t meet your requirements, MJM Industries delivers custom flat flex cable assemblies designed to perform in your unique application. Our in-house engineering, U.S.-based manufacturing and proven processes ensure assemblies that are reliable, durable, and built to your specifications.

Ready to get started? Contact MJM Industries today to discuss your project and see how our team can design and build custom flat flex cable assemblies solutions that are tailored to your needs.