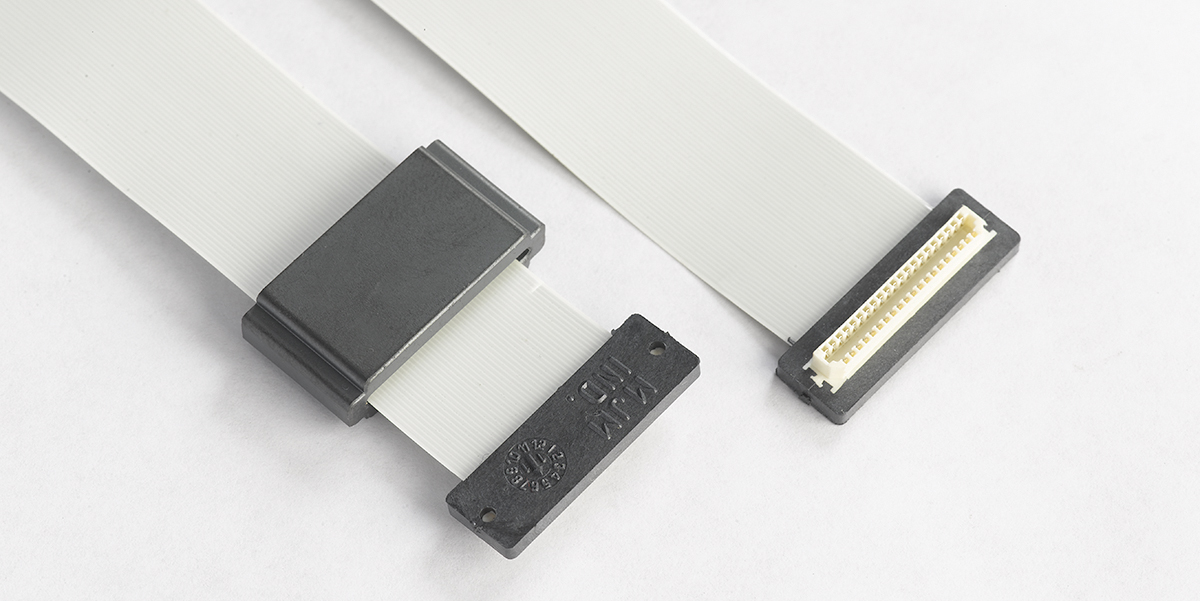

Our flat flex cable assemblies can be developed to suit the needs of any simple or complex project.

MJM Industries offers a broad variety of options when it comes to flat flex cable assemblies. These

assemblies are created unique, custom tailored to fit the needs of our customers. Our flat flex cables

are specifically unique because of the liquid crystal polymer over-molding process we use which

makes our cables more durable than our competitors. While other manufactures may use a similar

process, our overmolding process is solid, meaning no holes are in the over mold. These one-of-a-

kind cables are quality-made for a long-serving component of your product.

Our products are developed and constructed in-house by utilizing our on-site engineers and latest

technologies. We also provide you with prototypes for new product development projects. The

finished product is completely custom to you. We can even add your logo to the cable when

preferred.

MJM Industries holds our own fully-equipped machine shop which allows for accommodations to all

projects. We are also capable of 3D-printing for visionary components. Our updated technology

allows us to represent the high-quality standards that we set for ourselves.

Our products are not only reliable but able to be repeated upon your request. Our flat flex cable

assemblies set us apart because of the number of optional features which we are able to provide.

These features include foil shields, separated lead ends, selective grounding, ferrites, specialty pin

outs, custom cables lengths and transition boards. This is what makes our product truly custom

tailored to your needs.

All of our flat flex cables are not only made in the U.S.A. but are fabricated in-house. Unlike off-

shore companies, we have a quick and personable response time. Our assemblies have been used

within several industries including medical, industrial automation, machine control, avionics, PLC,

flat panel display, and retail panel display. Standard products include connection orientations as

required, custom lengths and folding options, one piece over mold strain reliefs, option ZIF endings,

LPC over molded shells, and 0.5mm pitch laminated polyester ribbon cable.

MJM Industries provides 31, 41, and 51 position, male and female flat flex cable assemblies for the

flat panel display industry. Each connector is over-molded in a liquid crystal polymer to ensure the

highest level of ingress protection for your application. Our flat flex conductors are easily routable

due to their size and our capability to create bends and folds within the assemblies, for your benefit.

Utilizing reflow technology, our products are more reliable than other manufacturers. Other

manufacturers use a resistance welding and traditional soldering process, which may compromise

the conductors. Our proprietary hot bar process guarantees the most dynamic application currently

available on the market. We use several different types of shielding including EMI shielding, ferrites,

and floating shields.

All of our cable assemblies are RoHS, REACH, and WEEE compliant. We use alloy plating on our

conductors to prevent tin-whiskering and shorting.

Our over and beyond expectations include the unique groundings which we offer via laser which

drains static from the connection. We offer a DF9 series for board-to-board connectors. These

connectors have provided above-expectations for the use of touch screen devices. The Hirose DF9 is

overmolded to 0.5MM pitch laminated polyester flat flex cable which creates a creative

interconnection to flat panel display systems. Our overmold process creates a unique appearance

accompanied by the durability you demand. The display cable meets both Flat Panel Display

Interface (FPDI-1) and Video Electronics Standards Association (VESA) stipulations.

Cable:

- Insulator: Polyester cable

- Plating: Tin

- Conductor: Flat solid 33 AWG equivalent

- Length tolerances: (under 12’’): +/- 0.10” (over 12”): +/- 0.25”

- Length is measured from end to end in inches, including connectors

Contacts:

- Material: Phosphor copper

- Finish: Tin or gold plate

- Insertion Force: 197 g/6.94 oz. (.4343 lbs nominal)

- Withdraw Force: 30 g

Electrical Connector Specifications:

- Contact resistance: 50 milliohm (maximum)

- Dielectric withstanding voltage: 300V RMS (minimum) @60 HZ/ 250V AC/ 1 min

- Current rating: 0.50 amps

- Insulation resistance: >109 @ 500V DC

- Hirose DF9-31,41 & 51 position

Optional Features:

- Ferrites

- Foil Shields

- Specialty Pin-outs

- Selective Grounding

- Shielding

- Drain wire

- Customer Cable Lengths and folds

- ZIF ends

- One piece over-molding strain reliefs

- Custom Engineering

- Logos

- Special packaging

- Inventory program