Automated Wire Processing in Detail

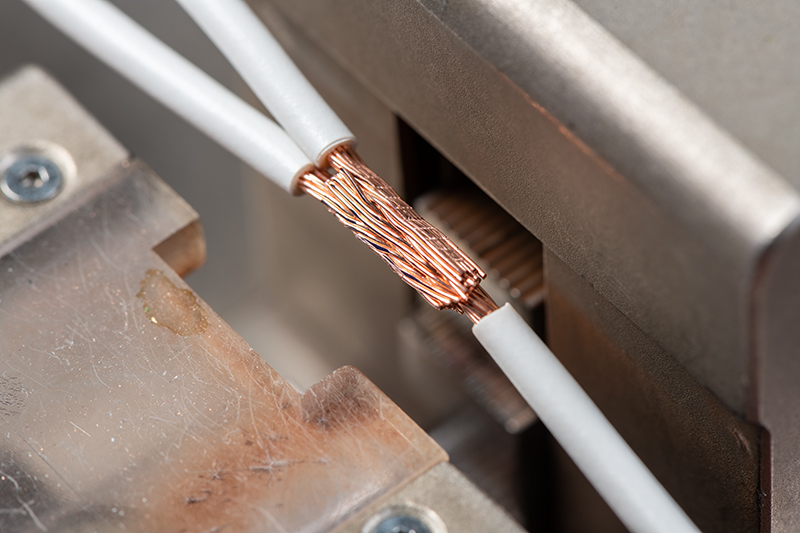

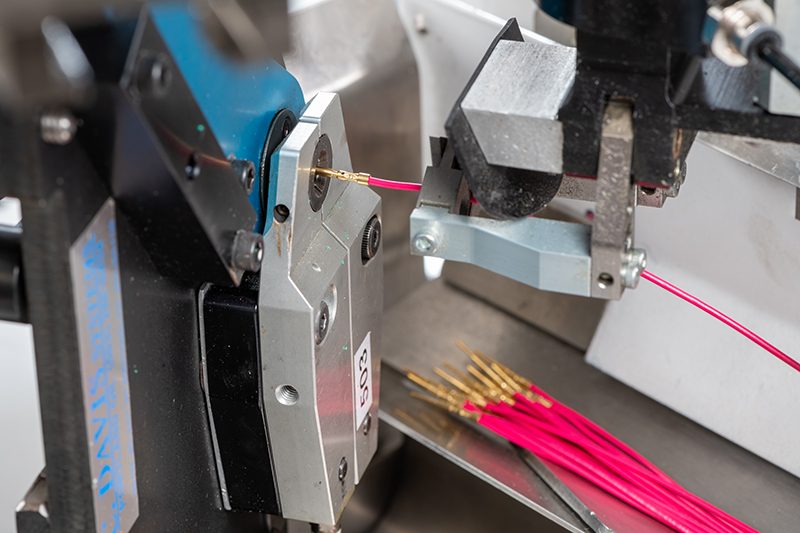

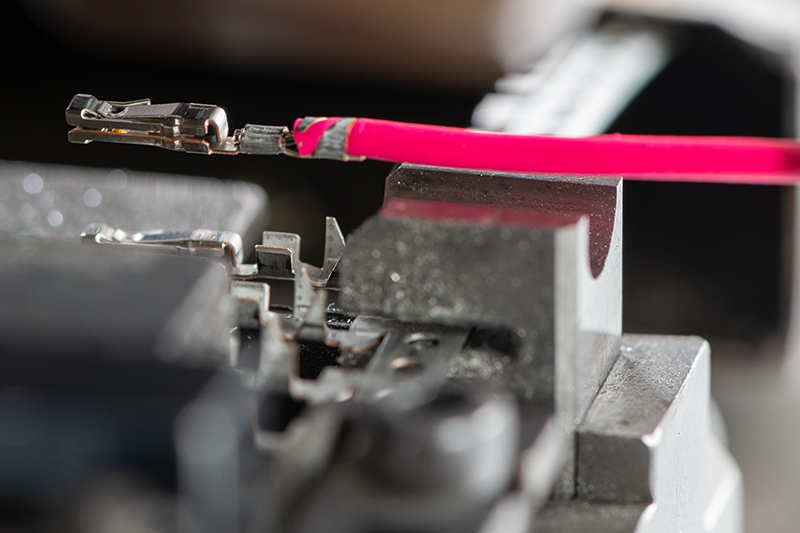

Automated wire processing is completed by pieces of equipment that accurately measure discrete wire and then cut it to a specified length. This equipment comes in two types. The first type automatically measures, cuts and strips, while the fully automatic adds crimping to its toolbox. Either type can strip either one or both ends of the wire to a predefined length, while the fully automatic machine mechanically attaches contacts or terminals to one or both ends by crimping the part onto the stripped end of the wire. The fully automatic equipment is fully programmable and adjustable and offers several quality inspection tools such as crimp quality monitoring, pull testing, and crimp height measuring. Implementing all of these inspection processes helps to guarantee that the final assembly of each product meets UL, IPC-620, manufacturer, and customer workmanship standards.

Why MJM for Automated Wire Processing?

- Scalability – From low-volume prototypes to full production

- Customization – Tailored to your design, specs, and timeline

- Speed & Accuracy – Reduced lead times with no compromise on quality

- ISO 9001:2015 Certified – A commitment to quality and continuous improvement

Automated Wire Processing

At MJM Industries, we specialize in automated wire processing solutions designed for precision, efficiency, and repeatability. Our advanced equipment and engineering expertise ensure consistent quality for a wide range of custom cable assemblies and wire harnesses.

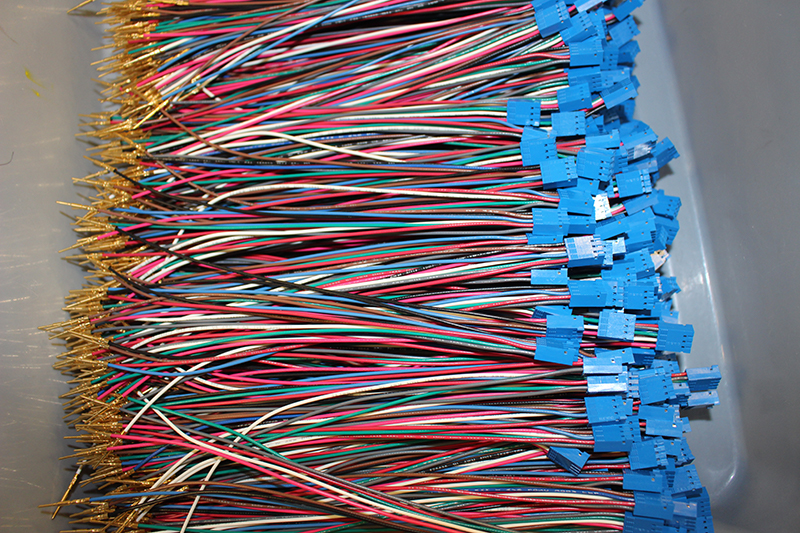

Our automated wire processing capabilities are ideal for high-volume production environments where accuracy and turnaround time are critical. MJM’s in-house systems are optimized to handle:

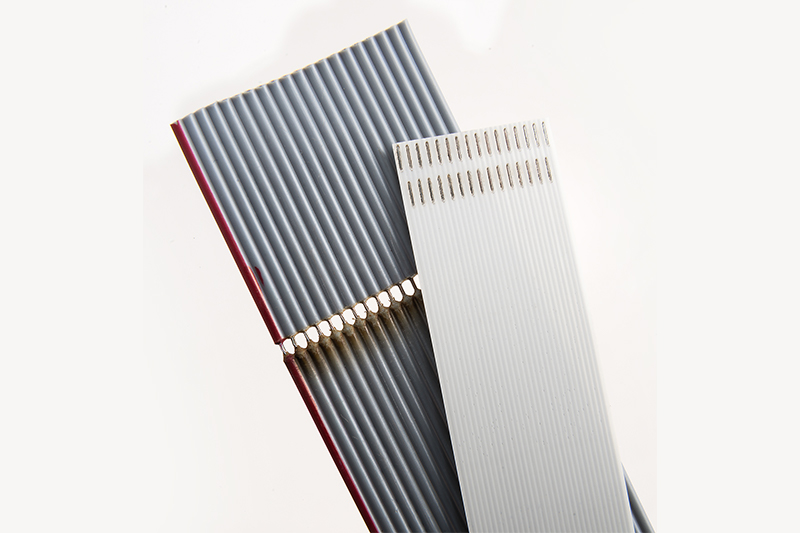

- Wire cutting and stripping (single- and multi-conductor)

- Crimping and terminal insertion

- Twisting, tinning, and labeling

- Wire marking (inkjet or hot stamp)

- Custom wire kitting and bundling

Built for Engineering-Grade Reliability

With engineers in mind, MJM’s process control ensures:

- Tight tolerances and exact wire lengths

- Repeatable terminations and secure crimps

- Traceable production data and quality assurance

- Whether you’re prototyping or scaling to full production, we maintain rigorous standards throughout the entire automated wire processing workflow.

Custom Made by MJM Industries

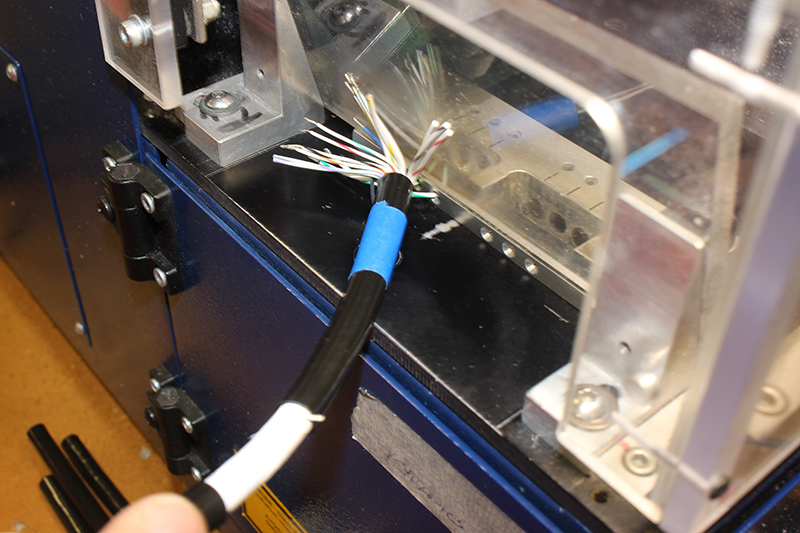

MJM Industries employs a custom ERP system that handles job schedules, real-time material consumption, and signaling replenishment demands to the purchasing department. For automated wire processing, MJM Industries uses machinery that allows for a unique process that measures, cuts, strips, crimps, and coils. We not only have the ability to crimp traditional open barrel “F-Style” crimps, but we also can crimp closed barrel, and screw machine terminals. Our equipment portfolio allows for the cutting of wire and cable from 28AWG to 4/0. We perform our stripping on V-blade, die-blade, and rotary stripping equipment, as well as laser stripping. Equipment ranges from benchtop to free-standing stations. With our most recent state-of-the-art wire processing machine, we employ crimp quality controls. We are also able to identify parts that do not fit within the controlled parameters and sort those from production.

With the use of wire and cable de-reelers paired with coiling bowls and tie machinery, we can allow for bundling of longer-length wire and cable from 6” to 14” coil diameters. We are also able to include cable lengths of several feet to several hundred feet, depending on outer jacket diameter. In addition, MJM Industries can also perform window strips on either wire or cable and multi-level stripping of coax and triax cable.

Another unique capability of our wire and stripping services is that our dual-axis benchtop CO2 laser stripping allows for small gauge wire insulation to be vaporized, meeting IPC 620, class 3 stripping standards. Our laser stripping meets the requirements used for high-performance electronic products where performance and safety are critical. In these cases, equipment downtime cannot be tolerated and needs to perform to the highest standards. Industry examples where wires might require laser stripping include high-end medical, aerospace, defense, test & measurement, and automotive applications where system reliability is critical.

Choose MJM Industries for Your Automated Wire Processing Services

Connect with our team of engineers and production personnel to receive in-depth education on our equipment capabilities and automated wire processing services.

Contact us today to experience our intelligent engineering and innovative manufacturing capabilities with wire processing.

Our Experience

No task or request is beyond what we’ve probably already experienced.Our Experience

MJM Industries has produced millions of wire harnesses and cable assemblies that have made their way into thousands of products around the world.

Our Quality

We stand behind every assembly that leaves our facility.Our Quality

You can rest assured that your project is exactly what you expect. We don’t just spot check our work, but each assembly is inspected and tested for accuracy and quality.

Our Team

We've assembled a team of experts that specialize in assembly.Our Team

From engineers, to project managers, to plant managers, our team of experts come together to provide exactly the products you’re counting on.

Our Commitment

To provide our customers solutions that exceed expectations.Our Commitment

Our daily mission is to provide our customers engineering and manufacturing solutions resulting in products and services that exceed their expectations.

As a contract manufacturer, MJM Industries offers a variety of manufacturing processes and other value added services that allow our customers to realize greater productivity and profitability. From design services to custom overmolding, cable assembly, packaging, and testing, we strive to provide a complete contract manufacturing program for customers that demand reliable assemblies with on-time delivery.

Contact Us for all your wire processing needs. Call us. Email us. Or use the form below.

We’re ready to help make your job easier by providing the quality parts your company needs to keep your operation running smoothly!